600 kw ammonia cooler to supply glycol at -8° c with floating condensation (mft)

INDUSTRIAL REGRIGERATION

INDUSTRIAL REGRIGERATION

INTRODUCTION

The RFU ammonia-based chillers are designed with a compact format to optimise the space and reduce the ammonia charge, making them the best solution where space is limited, and where there are restrictions on the refrigerant charge used.

RFU chillers are designed with 2 or 3 compressors and drivers with VSD to offer the most

cost-effective solution in the market to deal with changing circumstances and different operating requirements.

TECHNICAL SPECIFICATIONS

01.

Ammonia condensation can be done by using a remote condenser (air, evaporative, adiabatic) or by integrating an exchanger in the chiller itself to condense ammonia with water.

02.

CIntegral control system with a Siemens S7-1200 PLC with PROFINET communication, Schneider Electric 10” screen and inverters for com-pressor control. Remote access available.

03.

We offer the possibility of designing and manufacturing the equip-ment with an external housing, protecting all the elements against the weather.

04.

Possibility of integrating pumping groups for the transmission of cold liquid from the evaporator or hot liquid from the heat recovery PHE.

05.

The flexibility to adapt our solutions to the specific needs of the project to offer the best solution.

ADVANTAGES

| Natural refrigerant | Ammonia (NH3) based proof solution which is exempt from future F-gas regulations. |

| Plug and Play solution | To reduce installation costs: using our chiller you will reduce the ammonia field piping in your installa-tion. |

| Low refrigerant charge | Compact format to optimise the space and reduce the ammonia charge. |

| Mechanical Expansion Valve | To avoid electronic failures. |

| Heat Recovery (Desuperheater) | We can include an additional heat exchanger in the hot gas circuit to reach a highest ener-getic. |

| Fully welded steel piping | To ensure a long working life without leaks with an outstanding reliability. |

INFORMATION

Cooling capacity

378kW – 2325kW

Shaft power

128kW – 681kW

EER

2.95 – 3.41

Cooling capacity

656kW – 2156kW

Shaft power

141kW – 389kW

EER

4.65 – 5.54

Cooling capacity

418kW – 13705kW

Shaft power

132kW – 410kW

EER

3.16 – 3.34

Cooling capacity

510kW – 2065kW

Shaft power

101kW – 383kW

EER

5.04 – 5.39

RELATED PROJECTS

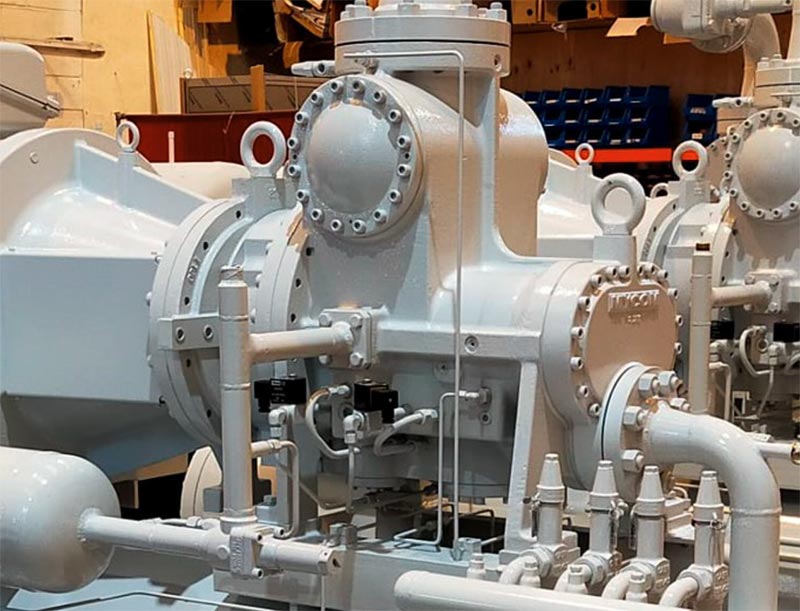

600 kw ammonia cooler to supply glycol at -8° c with floating condensation (mft)

Designed and manufactured to optimise space on board fishing vessels.

Climate control system designed to offer an efficient and versatile solution in outdoor applications.