Provide the most possible gentle fish transfer in between RAS tanks as well as for the last transfer into the processing facilities.

AQUACULTURE

AQUACULTURE

INTRODUCTION

We design comprehensive logistical systems which include pumping, classification, counting and harvesting, using technology that takes care of every detail within the process. We have references for such different species as salmon, trout, cod, sea bass, bream, etc.

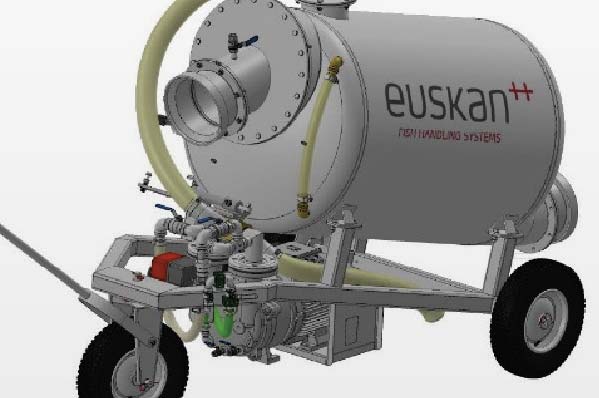

Adaptable to different sizes from just a few grams to more than 15kg.

Manufactured in stainless steel, guaranteeing durability, hygiene and corrosion resistance in marine or industrial environments. Connections with integrated check valves, ending in standard DIN/ANSI flanges for ease of integration within existing systems. “Easy valve change” mechanism, allowing for swift inspection and replacement without the need for special tools, and Control panel with programmable PLC, and HMI touchscreen for parameter display and manual control.

TECHNICAL DATA

01.

Unlike conventional vacuum systems, our technology provides an absolutely stable inflow. This eliminates back pressure and turbulence, guaranteeing a smooth transfer with significantly lower stress and physical impact, even for fish weighing up to 15kg. MonoCS systems guarantee constant flow with 2 tanks and one single pumping unit.

02.

This means the pumping equipment can be positioned below water level, maintaining the same key characteristics of constant flow. An approach that provides flexibility in land-based installations when designing the tanks and associated structures, with raised tanks, for example.

03.

Smoother transition (2-2.5 seconds) between the vacuum and pressure phases (rather than instantaneous, as in other systems), avoids potential harm to the fish resulting from over-generation or collapse of blood gases.

04.

Capacity regulation in real time by integrating variable frequency dives in any of the configurations.

05.

The system is properly configured to adapt to the specific needs of each client: single or double tank, single or double pumping system, mobile or containerised system.

05.

As the pumping equipment represents the heart of the transfer system, we offer a complete solution from the point of suction as far as discharge, including counters, classifiers, water separators, etc.

ADVANTAGES

| Maximum fish welfare | By generating a fish-friendly pumping process (sheer and laminar flow, reduced acceleration gradients). |

| Customisation | Whether you are moving large smolt or broodstock, our systems are built for the task. The water flow and transfer speed can be precisely adjusted according to the species, size and specific conditions of your installation. |

| Maximum productivity | Designed to minimise stress during the transfer process, which speeds up each individual’s process of adaptation and reduces the mortality rate. Greater quality and productivity. |

| High cost-benefit ratio | Technology capable of generating fish-friendly transfer flows with reduced footprints and different layouts. |

| Adapted to fish size and facility needs | Whether you are moving large smolt or broodstock, our systems are built for the task. Water flow and transfer speed can be precisely adjusted to the species, size, and conditions in your facility. |

INFORMATION

Diameters

from 6” a 16”

Power

up to 200kW

Maximum suction height

from 4m to 8m

Maximum discharge height

from 8m to 12m

Pumping capacity

from 10m³/h to 1000m³/h

Maximum fish size

from 0,1kg to 15kg

Automatic data collection for monitoring and documentation

RELATED PROJECTS

Provide the most possible gentle fish transfer in between RAS tanks as well as for the last transfer into the processing facilities.

Provide the gentlest fish transportation from sea cages to killing station keeping high production capacity and with long pumping distances.

Improving volume and quality harvest size salmon 5 kg average 300 tons per week